10 Essential Tips for Using a Carbon Weaving Machine in 2026

In 2026, the world of manufacturing is evolving rapidly. The carbon weaving machine stands at the forefront of this change. These machines are crucial for producing lightweight and strong materials used in various industries. However, operating a carbon weaving machine is not without its challenges.

Many users struggle with common issues. Mistakes can lead to wasted materials and time. Yet, learning from these experiences is vital. Each challenge teaches valuable lessons. Attention to detail is key. Proper settings can make a significant difference in product quality. Effective maintenance extends the machine’s lifespan, which can be overlooked.

Every user should keep evolving their skills. Embracing new techniques is essential for improvement. Experimentation can lead to innovative solutions. Moreover, sharing knowledge among peers fosters a collaborative environment. The journey with a carbon weaving machine is about continuous growth. Each step forward should be a goal, inspiring greater achievements.

Understanding the Basics of Carbon Weaving Machines

Carbon weaving machines have transformed the manufacturing landscape. These machines are designed for creating carbon fiber products. Understanding their mechanics is essential for efficient use.

Basic components include the creel, which holds the carbon fiber spools. The machine weaves the fibers together to form a composite material. Proper tension and alignment are critical. Incorrect setups can lead to defects, impacting the final product. Operators must regularly check these settings to ensure quality.

Training is vital. New users often struggle with the machine's intricacies. Regular practice can lead to better outcomes. Reflecting on errors helps improve skills. Setting realistic goals is essential, as the learning curve can be steep. Working with these machines isn't straightforward, but dedication pays off.

10 Essential Tips for Using a Carbon Weaving Machine in 2026

| Tip Number | Tip | Description |

|---|---|---|

| 1 | Understand the Machine | Familiarize yourself with the features and controls of the carbon weaving machine. |

| 2 | Keep the Workspace Clean | Ensure that your workspace is organized and free from debris to avoid any mishaps. |

| 3 | Regular Maintenance | Perform regular checks and maintenance to keep the machine in optimal condition. |

| 4 | Use Quality Materials | Always use high-quality carbon fibers for better results. |

| 5 | Follow Safety Protocols | Adhere to safety guidelines to prevent accidents while using the machine. |

| 6 | Test Settings | Run test patterns before starting your actual project to check settings. |

| 7 | Monitor Tension Levels | Keep an eye on the tension of the fibers for consistent weaving. |

| 8 | Document Settings | Keep a log of settings that work well for future reference. |

| 9 | Seek Training | Consider training or tutorials for advanced techniques and tips. |

| 10 | Evaluate Final Product | Assess the final product for quality and make notes for improvement. |

Key Features to Consider When Choosing a Carbon Weaving Machine

When choosing a carbon weaving machine, certain features should be prioritized. Look for the machine's weaving speed. A higher speed often means increased productivity. However, be cautious; faster isn’t always better if it compromises quality. Precision in weaving is essential to ensure that the final product meets specific standards.

Consider the machine’s compatibility with various carbon fibers. Different fibers require different tension settings and adjustments. Not all machines perform equally well with every type of fiber. If your projects involve multiple fiber types, pick a versatile machine. This may save you time and enhance your team's efficiency.

Tips include understanding the machine's maintenance needs and regular servicing. Neglecting maintenance can lead to costly repairs and downtime. Create a routine maintenance schedule early on. Finally, user support is vital. A helpful, responsive support team can make a difference when you troubleshoot issues. Select machines backed by good resources and information.

Step-by-Step Guide to Operating a Carbon Weaving Machine Effectively

Operating a carbon weaving machine can be intricate. Knowing how to approach it effectively is vital. According to a recent report by the Global Composite Materials Market, demand for carbon fiber products is expected to grow by 10% annually through 2026. This makes mastering the carbon weaving process essential for manufacturers aiming to meet the industry’s needs.

Start by familiarizing yourself with the machine's components. Each part plays a crucial role in weaving carbon fibers. Adjustments need to be precise. A slight misalignment can result in significant flaws. Review the setup regularly. Check for wear and tear on the weaving tapes. Minor damages can lead to larger issues, affecting the quality and consistency of the product.

Regularly monitor the tension and speed settings. Too high tension can break fibers. Conversely, low tension can lead to loose weaves. Aim for a balanced setting. Data reveals that maintaining optimal tension can increase efficiency by 15%. Operating the machine requires keen observation. Mistakes often teach lessons that improve future performance. Embrace the learning process.

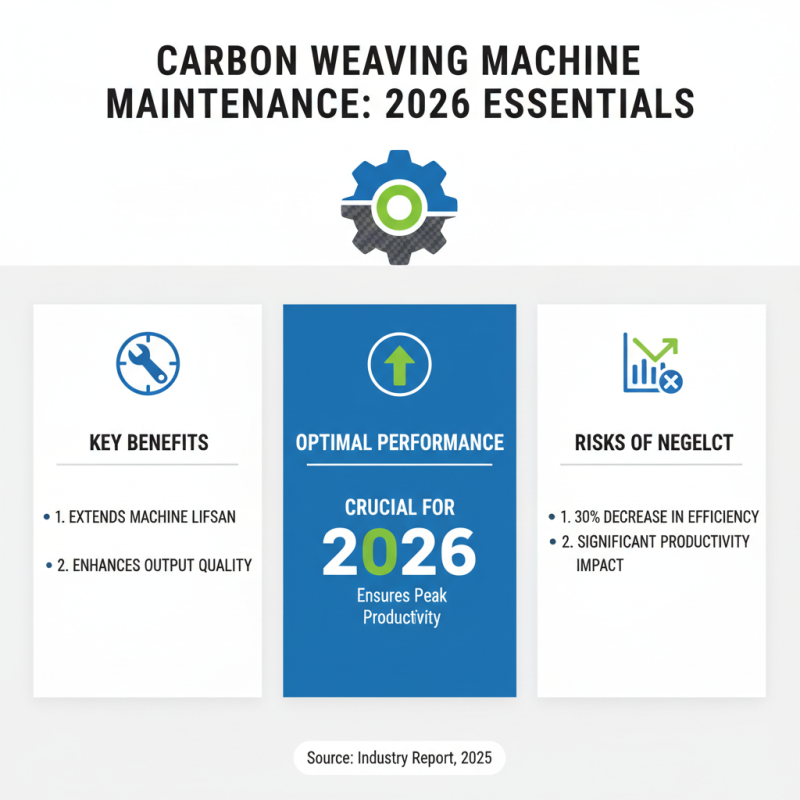

Maintaining Your Carbon Weaving Machine for Optimal Performance

Maintaining your carbon weaving machine is crucial for ensuring optimal performance in 2026. Regular maintenance extends the machine's lifespan and enhances the quality of your output. According to a recent industry report, failing to maintain equipment can lead to a 30% decrease in production efficiency. This can significantly impact your overall productivity.

Daily checks are important. Inspect components for wear and tear. Dust and debris can accumulate, causing issues. A 2023 survey revealed that almost 40% of operators faced downtime due to lack of maintenance. Cleaning your machine regularly is essential. Lubricate moving parts according to the manufacturer's guidelines to prevent friction-related issues. Poor lubrication can lead to overheating, resulting in malfunction.

Training staff properly is often overlooked. Many users fail to recognize the importance of operator training in maintenance. In fact, 25% of maintenance-related failures stem from improper use. Establish a routine that includes both technical checks and operator education. Over time, this will create a culture of care, enhancing the performance of your carbon weaving machine.

Common Mistakes to Avoid When Using a Carbon Weaving Machine

Using a carbon weaving machine can be challenging. Many users fall into common traps. One frequent mistake is overlooking the machine's calibration. Proper calibration ensures that the tension is right. If the tension is off, it can ruin your entire project. Check it often.

Another mistake is neglecting the maintenance schedule. Failing to clean and lubricate parts can lead to breakdowns. Inspect the machine regularly for dust or debris. Dust particles can impair performance and compromise the quality of the weave.

Many users rush through the setup. Taking your time to adjust settings can save you from future headaches. Also, always test your weave with small samples. This helps in identifying any potential issues. It’s often better to take longer on setup than to face costly errors later on.

Related Posts

-

Top 10 Smit Weaving Machine Features You Need to Know

-

How to Choose the Best Carbon Fiber Weaving Machine for Your Needs

-

How to Effectively Use Textile Treatment for Enhanced Fabric Durability

-

Why Terry Towels Are Essential for Your Home and How to Choose the Best Ones

-

How to Choose the Right Home Textile for Every Room in Your House

-

Why Understanding Fabric World is Essential for Fashion and Design Trends